The borosilicate glass (even known with its trade name as pyrex) is a particularly robust material, known for its resistance qualities against shocks, as thermal shock, but also for its low expansion coefficient. Borosilicate glass (or sodium-borosilicate glass) is made mainly of silica (70-80%) and boric oxide (7-13%) with smaller amounts of the alkalis (sodium and potassium oxides) and aluminium oxide. This type of glass has a relatively low alkali content and consequently has both excellent chemical durability and thermal shock resistance, meaning it doesn’t break when changing temperature quickly.

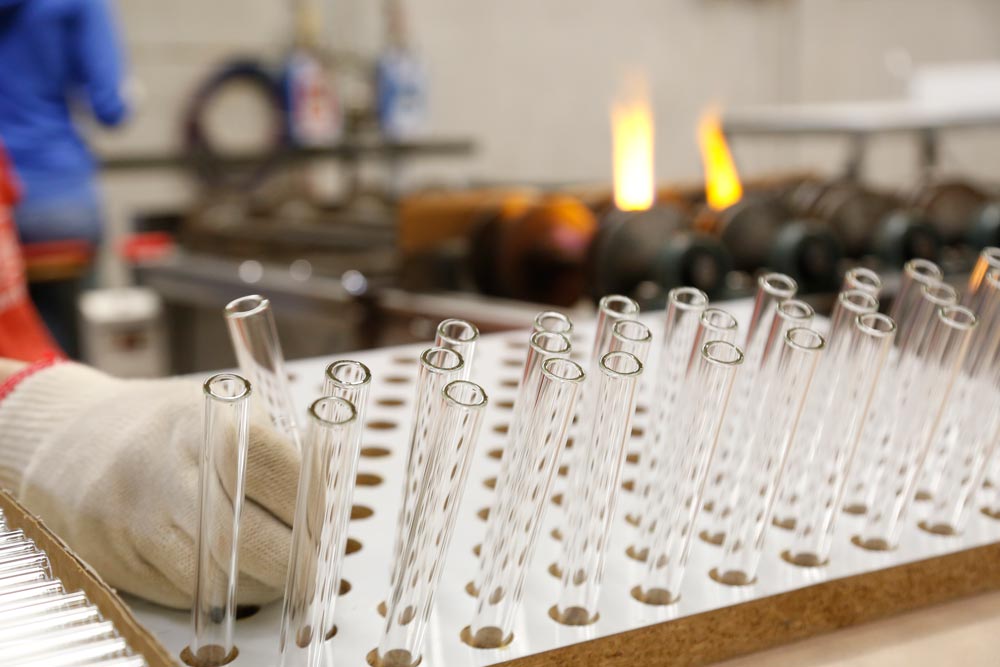

As a result of these properties, sodium borosilicate glass is widely used across the chemical industry, pharmaceutical sector, for ampoules and other containers and overall high intensity lighting applications.

TEMPERATURE CHANGE RESISTANCE

When glass is heated until its lowest boiling point, the thermal expansion and low thermal conductivity bring to stress and compression. If, the heating or cooling speed turns to be too high, the glass breaks.

MECHANICAL STRESSES

From a technical point of view, the glass behaves as a perfect elastic mean and this means that, if the maximum range of elasticity is exceeded the material cannot acquires a plastic deformation rather it breaks.