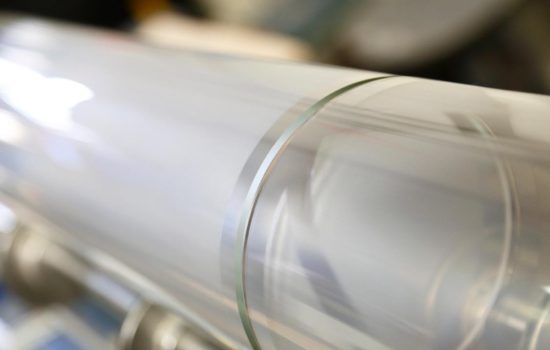

CUT

The borosilicate glass tube appears as raw materials in different pipes with standard commercial length of 1.500 mm. in a wide range of diameters and thicknesses. The first necessary operation to do in order to obtain a finished product is the cut according to a precise cut. Usually it is used the thermal shock cut method.

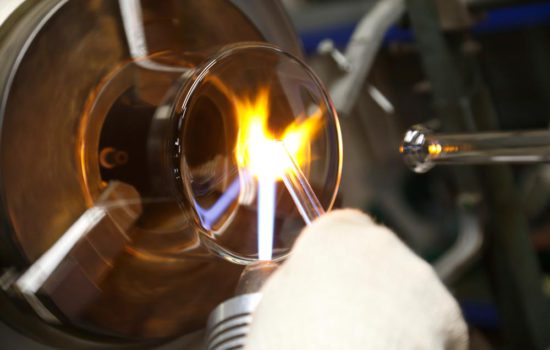

BURNING

The previously cut pipe is reburned in its borders. This process, done handmade with the sustain of specific flames, confers a greater robustness to the borders and a better finishing both functional and aesthetical.

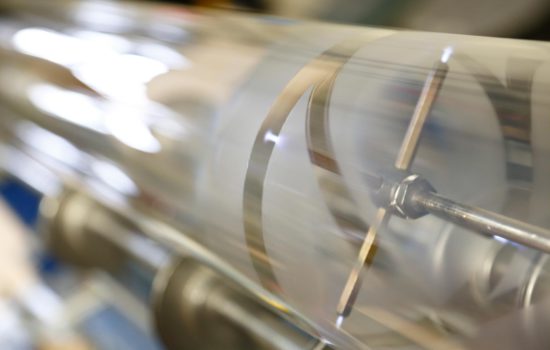

WELDING AND BLOWING

The borosilicate glass working process is done, usually, with the use of mechanical lathe. The master is able to model the tube by heating and melting it, thanks to specific flames, to obtain customized shapes according to the different requests of the clients. From the melting point the master is able to realize weldings of pipes with different diameters and blow that, with the help of specific graphite outlines, guarantee the possibility to maintain the necessary tolerance measures for the production of lighting in series articles, laboratories, households, …

FIRING

Once all previous processes end, it is time for the last process of the borosilicate glass.

The firing consists of heating the glass and it is used to eliminate torsions generated during the formation, which make difficult the finishing processes, as for example, the cut. It is an essential step to eliminate the internal power generated for anomaly during heating or cooling.

Once the right temperature is reached, the object is maintained in this status for a period needed to assure the achievement of thermal uniformity of it in all of its components; the item is then slowly cooled untill a temperature lower than 50 degrees with respect to the temperature of firing is reached, lastly it is rapidly taken to room temperature.

CONTROL

Quality control is the last but not the least of all processes. It is always done by specialized people with the use of luminous tables useful to highlight every, even the smallest, flaw on the glass. Control is one of the most relevant activities, and it is useful to assure the client the guarantee of a reliable product, functional and aesthetically flawless at the same time.